Why is Quality so important for an organization?

© ICMCIC and Angela Gurau

Introduction

I will start with a basic idea … It’s a well-known fact that an organization (company, business or non-profit) is a complex system which is primarily designed to add value to all stakeholders: employers, legal owners, staff, customers, business partners, authorities, etc.

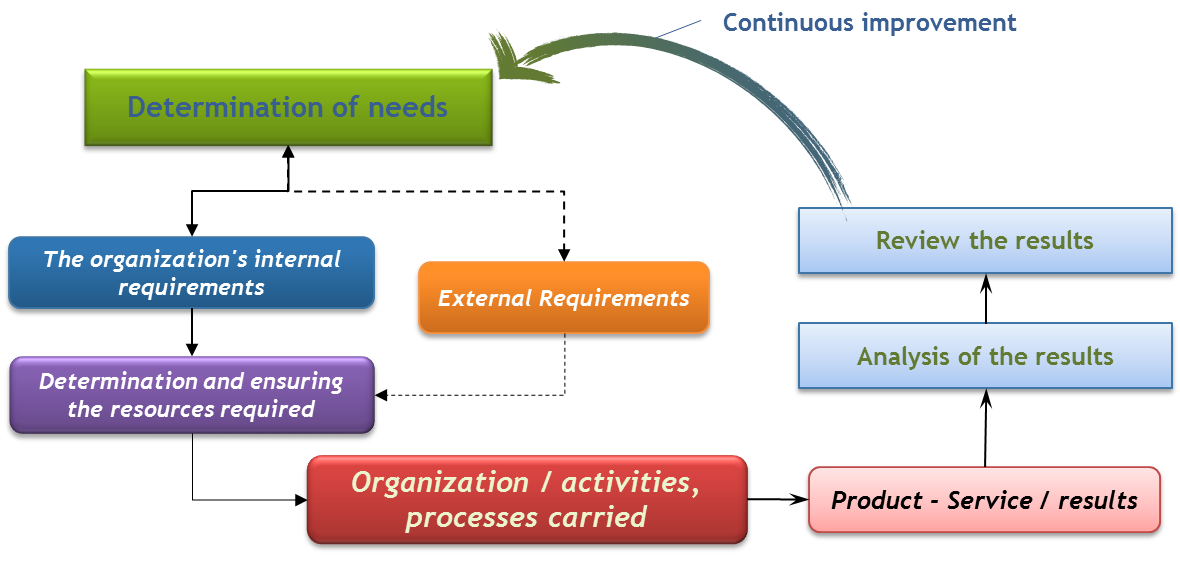

Any organization uses a management system to determine the needs of each stakeholder, to transform these needs into internal requirements, to provide the resources needed to meet all the requirements and to review the performances. (See picture below.)

There are many definitions for the Management System of an organization and I can give here two examples:

“A management system is the framework of processes and procedures used to ensure that an organization can fulfill all tasks required to achieve its objectives.” / wikipedia.org

“A management system describes the set of procedures an organization needs to follow in order to meet its objectives.” / iso.org

What is important here? Regardless of the size of the organization, regardless of its field of activity, any organization needs to manage internal processes in order to obtain the product or service requested by clients and to fulfill the established objectives. Each organization is unique and has its own identity and structure, so each organization must develop its own Management System so that it can be used and continuously improved.

Therefore, to have a management system, each organization should clearly define its own activities and internal processes, and these internal processes must be continuously improved, based on the analysis of the results.

What is “Quality”?

We can define the term “quality” in many ways, but the ISO family of standards gives a very concise definition: “quality - the degree to which a set of inherent characteristics fulfils requirements.” (ISO 9000:2005 – 3.1.1).

Note: At this time, the ISO 9000 and ISO 9001 standards are under revision.

This definition gives a general sense of "quality", but we can watch at The Chartered Quality Institute (thecqi.org) which gives the following definition: “an outcome – a characteristic of a product or service provided to a customer, and the hallmark of an organization which has satisfied all of its stakeholders.”

So, we must consider the customer and the degree to which the product or service meets the needs of all stakeholders. We can say about the quality of a product or service that this is “poor”, or “good” or “excellent”, but this must be in accordance with something, we must have a reference to give such a description.

Nowadays, all organizations have to face some challenges in their business environment: the economic crisis, globalization, as well as the competition in its market. Moreover, the increase in technology and especially in IT, requires new actions. For example, it is well known that the e-commerce has opened new doors in business, which means an increased competitive environment. And if we consider the area of social media, we realize that organizations that do not meet the "quality" of products or services have no chance to stay on the market. The conclusion is that “Quality” is very important for every business!

What might or could a company do to provide quality products or services?

This is such a great subject! We could talk days and days about it! But in this article I will touch only a part of it, namely the one that relates to the Quality Management System.

What is a Quality Management System?

Returning to ISO 9000:2005, we can find this definition: “management system to direct and control an organization with regard to quality”.

In other words, a Quality Management System is “a set of interrelated or interacting processes used to guide and lead an organization so that its products or services meet the established requirements”.

Specifically, the Quality Management System focuses on the processes of the organization, customer and continuous improvement.

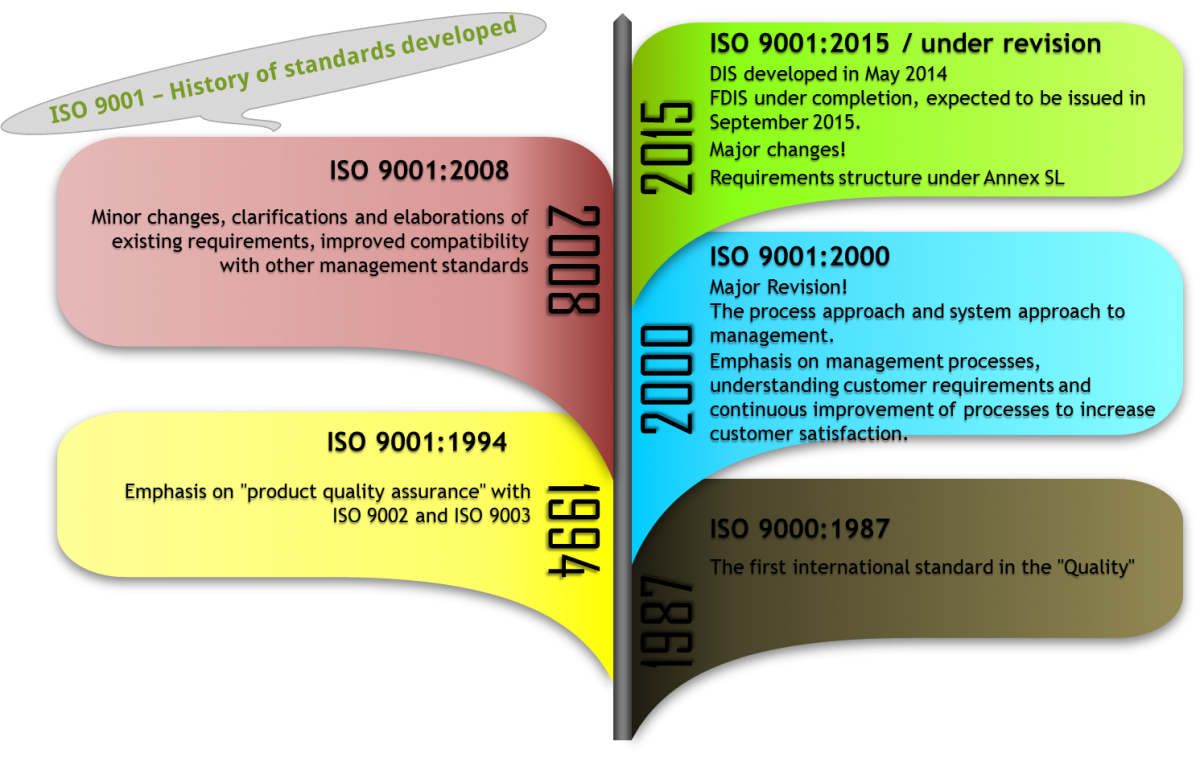

Quality Systems history begins since the interwar period, in the early 1920s and over the years has undergone several transformations, due to the needs of organizations and business environment. This means that ISO 9000 family standards went through several revisions. I do not intend to present here this history; but I can summarize it:

Until the new revision of the standards are developed (in September 2015), the current standard ISO 9001: 2008 is available, and it provides the framework for how a company sets (designed and implemented) the Quality Management System that will meet their needs.

Any Management System (whether it is quality, environment, energy, etc.) is developed based on PDCA cycle model, which is known as “process-based model system”. So, if an organization wants to fulfill the requirements for a quality management system, it must develop its management system on a process approach. This is a very important principle of quality management, and the new revision of the standard (expected in September 2015) makes an emphasis on "the process approach". From this point of view, we can say that the internal processes of an organization are very important for delivering quality products or services. But it is not the single one … there are actually, eight quality management principles and any organization must take these into account:

- Customer focus

- Leadership

- Involvement of people

- Process approach

- System approach to management

- Continual improvement

- Factual approach to decision making

- Mutually beneficial supplier relationships

Every principle from the above list has its own importance. But, in this article I will focus on only the first of them.

The first principle “customer focus” is very important. Everyone will agree that an organization depends on its customers, and that the organization cannot exist unless there are clients who buy its products and services. For this reason, the organization must understand the requirements of its customers and should focus to exceed those expectations and understand their requirements even further.

But, let's do an exercise: suppose a company that produces shirts receives a request from a major customer to deliver them a small amount of evening dresses. How will the company respond? Will it try to respond to customer requirements? Or, will they make their own broader analyses to lead to optimal final resolution? Of course this is not just about the company's ability to produce what the customer wants, but mostly it's the final result: if the activity (production and delivery of evening dresses) will bring profit, then they will organize their internal processes and they will provide the necessary resources to meet customer requirements. But, if this activity will bring financial loss, they will have to respectfully decline and eventually, recommend an alternative specialized manufacturer to their client. So what is to remember is that quality management must take into account the needs of owners, not only the needs of the customer.

A company is founded by its shareholders to be profitable, not to bring about loss.

Here's how a simple example can show that in fact a quality management system can be seen as a business management system. And, this is the trend. Because the new revision of the Quality Management System will bring a new emphasis placed on risk and opportunity. This is called "risk-based thinking" and it is an approach which the organization is required to employ in many areas of its Quality Management System. There are included clauses related to the design of processes, product and service, the design of the entire system. The risks and opportunities must be understood and appropriate actions must be taken to mitigate those risks or realize these opportunities.

Returning to our example above, that shirt company (and I think any company) will have its own analysis, for the effectiveness and efficiency of moving into production of dresses. What is this?

Efficiency means doing the things right. The definition is “Allows organizations to do the same amount of work with fewer resources”, so we could say this is about “productivity”. It is an important term in management, and all the executives must take it into account.

Effectiveness is about doing the right things. The definition is “Allows organizations to generate higher revenues, independent of resources required”, and this is commonly known as “the established goals of a company”.

These two important terms are also tools in management, if they are correctly measured and monitor. The ISO standard requires establishing methods to measure the effectiveness and efficiency of each process and to apply these measures to determine the effectiveness and efficiency of each process.

Conclusion

What have we demonstrated above?

- If an organization wants to deliver quality products and services, it must implement the requirements of the ISO 9001 standard.

- ISO 9000 family of standards relates to how an organization works and not directly to the results of this operation; refers to processes not directly to products (as a result of these processes).

- If the requirements of ISO 9000 standards are correctly applied and whether quality management principles are respected, then the quality management system will help the organization to:

- increased competitiveness

- improving outcomes, processes, products

- reducing costs

- In the new business environment, no organization should neglect "quality", and implementing a quality management system will become similar to implementing a business management system.

Constanta, Romania

Februarie 7, 2015

Angela Gurau

Engineer, specialized in "Automation and computers", Automation Faculty, Polytechnic University of Bucharest, year of graduation 1984

Over 20 years of engineering practice in various areas and on all levels, from trainee engineer to general manager.

Currently, Trainer and Senior Management Consultant, Lead Auditor for Quality Management Systems

Experience of over 14 years in “design, documentation and implementation of management systems according to ISO Standards”

Experience in internal audit, second party and third party audit, with over 300 audits performed.